Kompogas® Plant for Grenoble: City Authority Maximises Resource Utilisation and Decarbonisation

The City of Grenoble is gearing up for the future by optimising its waste management, recently commissioning a consortium including Kanadevia Inova to build a new biogas plant for the Centre de Compostage composting facility in Murianette. The plant, a flagship project for the production of green energy in the form of renewable methane, will start treating biowaste from the Grenoble metropolitan area at the end of 2027.

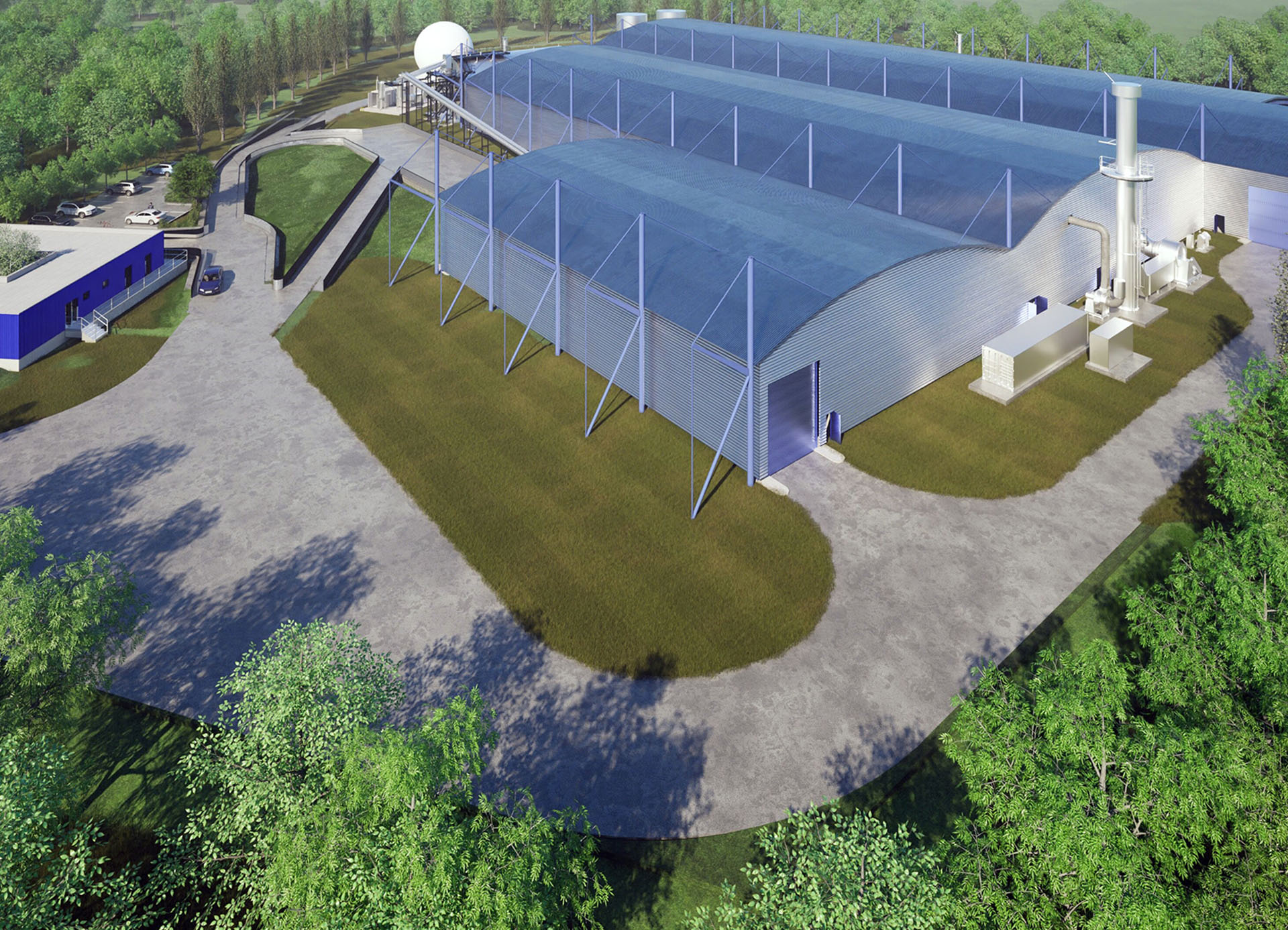

Grenoble, France. Zurich-based Kanadevia Inova AG has won a tender issued by Grenoble Alpes Métropole (GAM) for a major biogas plant in a consortium with leading French companies VINCI Construction Grand Projets and Spie batignolles. These three energy technology and project delivery specialists offered the optimum synergy for the execution of the plant, which will help the city drive regional decarbonisation efforts, substitute expensive natural gas imports and implement EU requirements. The comprehensive facility featuring state-of-the-art technology as well as setting new architectural standards, will be built next year 10 kilometres west of Grenoble on the site of the Murianette composting plant, and is scheduled to go into operation at the end of 2027.

Renewable Energy from Biogenic Waste

GAM has been operating a recycling plant treating biogenic waste and residual materials to produce compost for over 30 years. It is now being converted to a modern dry digestion process based on Kompogas®, an Kanadevia Inova technology that has proven its worth in practice all over the world. In addition to producing compost, the plant will also use the biowaste to generate renewable energy in the form of biogas. This will be done using a membrane gas upgrading system supplied by the Swiss green tech company that will convert the biogas into biomethane, a natural gas substitute that can be fed into the grid.

The digestion system will consist of a PF800 plug-flow digester with an annual throughput capacity of 12,000 tonnes of waste. Dry digestion will produce over one million Nm³/a of biogas from the biogenic substrates, with 4,000 tonnes of biofertiliser also obtained from the digestate resulting from the process. This will be used instead of artificial fertilisers in regional agriculture and plant breeding.

The carbon dioxide (CO2) contained in the raw biogas will then be separated from the methane in an M-Series Model S membrane gas upgrading system with a capacity of 200 Nm³/h to produce 600,000 Nm³ of biogas per year to be fed into the local gas grid. “This not only reduces expensive natural gas imports, but also replaces energy from fossil fuels with a renewable alternative reducing the carbon footprint of our region,” explains the representative of the city council responsible. He goes on to describe a special feature of the way the project will be delivered: “The experienced partners in the consortium bring us expertise in their specific fields and complement each other perfectly when it comes to delivering the plant. This will allow us to switch fertiliser production processes without interruption. The processing of the substrates will be gradually moved over from the old to the new plant, and once the changeover is complete the old one will be dismantled.”

Trio with Unparalleled Practical Expertise

VINCI, a global player in concessions, energy technology and construction, leads the consortium and is responsible for the processing and hygienisation of the biowaste as well as the refinement and odour treatment of the compost and natural fertiliser. Spie, in its capacity as a building, plant and infrastructure services specialist, is responsible for the entire construction project, including the earthworks. Kanadevia Inova is in charge of the turnkey digestion and gas upgrading system and for integration into VINCI’s processes. In addition, Kanadevia Inova’s French branch will provide O&M services for maintenance and spare parts management as well as services for the operation of the entire plant, with on-site support for an initial period of three years; operator training will also be provided by Kanadevia Inova’s experts in France.

“The synergy of our individual expertise made a persuasive case in the tender. We are very pleased to be able to deliver this contract for Grenoble Alpes Métropole in collaboration with our seasoned partners,” comments Fabio Dinale, Executive VP Business Development at Kanadevia Inova, on this latest project win. “Murianette is another project showcasing optimised circularity, regional decarbonisation and a secure, sustainable energy supply, with a signal effect for similar projects in the future,” Fabio Dinale continues. Plants like the one in Murianette make an important contribution to France’s efforts to combat gas pollution: waste is not wasted, but utilised meaningfully and profitably.

Kanadevia Inova’s project delivery team has already initiated pre-engineering. Construction work on the Kompogas® plant will start in 2025; the commissioning phase is scheduled to begin in mid-2027, and the aim is to have the plant operational by the end of 2027. Services have been agreed from 2028 to 2030 with the option of an extension.

Download media release

Download Image – Visualisation of the plant that will be built in Murianette (Copyright: Jean Lovera Architecte)