Future-proof Resource Economy

A comprehensive, reliable supply of renewable energy and the ability to produce regenerative fuels such as bio-LNG and bio-CNG are key to decarbonization and energy transition efforts. Whether it’s combined with a Kompogas® plant to create a complete solution or deployed on a standalone basis, BioMethan gas upgrading technology completes the range of Kanadevia Inova products enabling energy to be produced from any sort of waste or biomass – in this case employing an upgrading process to convert raw biogases into high-purity biomethane that can be used as a versatile energy source.

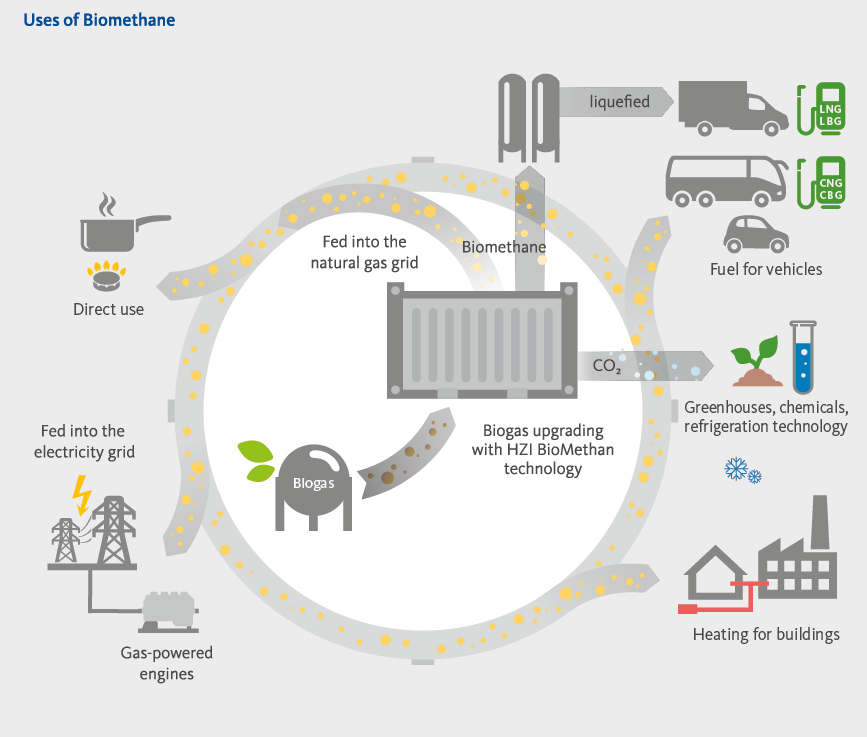

A by-product of the process is carbon dioxide, which can be used to generate additional revenues in the form of gaseous, liquefied or solid carbon dioxide deployed as an industrial product gas – for example in plant breeding, as an extinguishing agent or refrigerant, or as a raw material in the chemical industry.

Our BioMethan technology thus makes a major, direct contribution to efforts to increase the use of renewable energy, phase out fossil fuels, and decarbonise the society in which we live.

Advantages of BioMethan Technology

Raw gases from a wide range of different sources are suitable for upgrading: the digestion of municipal green waste, organic household waste or agricultural biomass. Sewage and landfill gas can also be converted into energy. This extends a plant’s value chain and promotes the circular economy.

Depending on the composition, the raw gas pretreatment may be required. Then comes the main process, where the carbon dioxide in the stream of gas is separated from the methane, with the resulting biomethane conditioned to the desired quality parameters.

In consideration of the requirements and circumstances, Kanadevia Inova offers two separation processes: amine scrubbing and membrane technology. Both guarantee the highest quality and maximise the purity of the methane.

Biomethane is highly versatile. It can be used to generate heat and power, or as a compressed or liquefied biofuel. Given that it is natural gas quality, it can be transported and stored in the existing gas grid infrastructure. Unlike fossil fuels, biomethane is a sustainable energy source and can be produced on a calculable basis.

The technology’s modular container construction allows several units to be combined, enabling plants to be designed flexibly to upgrade gas volumes of between 100 m3 and 2000 m3/h or even greater.

Biomethane plays a crucial role as an alternative to fossil fuels. It can take the form of biogas-based compressed natural gas (bio-CNG) or liquefied natural gas (bio-LNG). Kanadevia Inova’s add-on opens up a wide range of climate-friendly fuel options, for example setting up a bio-CNG filling station at the farm where the gas is produced, or transporting the gas in liquid form to an LNG fuel stop for heavy goods vehicles – a particularly attractive proposition for renewable fuels for transport.

Biomethane plays a crucial role as an alternative to fossil fuels. It can take the form of biogas-based compressed natural gas (bio-CNG) or liquefied natural gas (bio-LNG). Kanadevia Inova’s add-on opens up a wide range of climate-friendly fuel options, for example setting up a bio-CNG filling station at the farm where the gas is produced, or transporting the gas in liquid form to an LNG fuel stop for heavy goods vehicles – a particularly attractive proposition for renewable fuels for transport.