DPM AI System AI-based System for Early Detection of Digester Biology Disruptions

DPM AI System

AI-based System for Early Detection of Digester Biology Disruptions

Reliable, Automatic Monitoring of the Biological Process in Dry Anaerobic Digestion

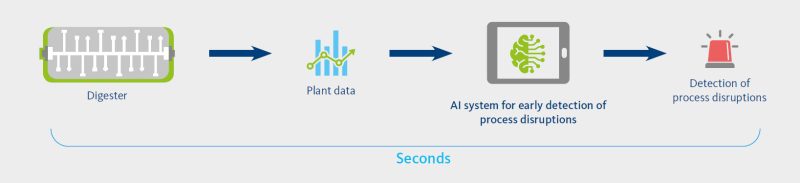

There are significant advantages to the automated, continuous monitoring of disruptions in the biological process in the digester with the help of artificial intelligence. These include rapid fault detection in a matter of seconds, increased plant availability, higher productivity, and time and cost savings versus conventional monitoring by means of laboratory analysis.

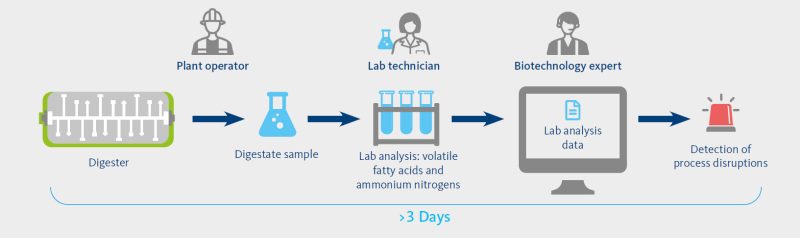

Current Situation

If disruptions to the biological process in the digester are detected too late, the result is reduced utilisation of plant capacity as well as lower gas production and financial losses. The most common method of process monitoring consists of laboratory analyses to measure volatile fatty acids and ammonium nitrogen in the digestate, which must then first be analysed by a process expert.

Our Solution

Thanks to artificial intelligence, the automated early detection of disruptions in the biological process in the digester is possible within a few seconds. In the event of a disruption, the system triggers an alarm and enables the operating personnel to intervene as quickly as possible. The system uses plant data available online from existing measurements, meaning that it can be used in many different types of plant.

The Benefits for You

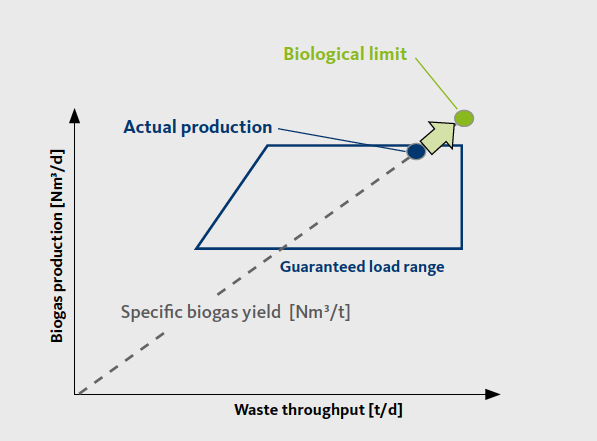

- The DPM AI solution, digestion plants can be operated closer to their biological limits, without the risk of a biological disruption.

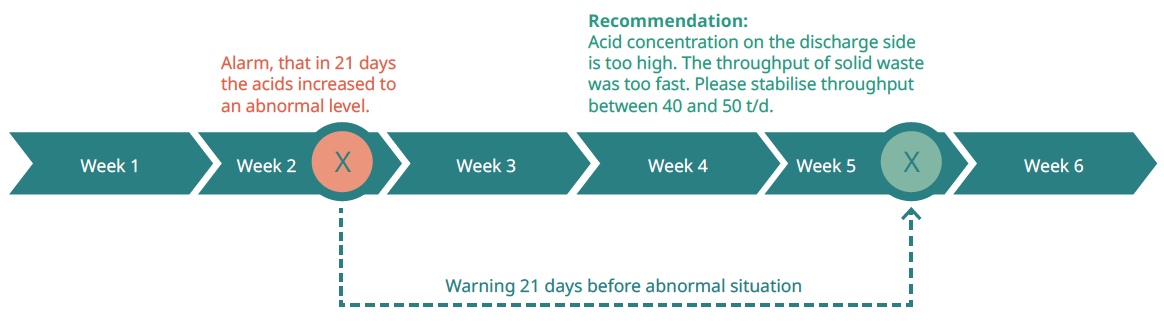

- Conventional laboratory analysis is no longer necessary and the continuous monitoring of the biological process eliminates the delay before a disruption is detected. Detection happens several weeks before disrutption.

- Results are output directly on-site as a visual alarm on the dashboard with details of the disruption, enabling immediate intervention by the operating personnel.

- A reduction in production lasting up to several weeks can be avoided. Plant availability can also be increased, reducing financial losses.

Intended Use

– Kompogas® plants

– All dry anaerobic digestion plants in continuous operation, regardless of the temperature.

– It can be used for retrofit as well if requirements are fulfilled.

System Properties

– Continuous monitoring and early detection of disruptions in the biological process

– Overall accuracy 99.5%

– Sensitivity 100%

DPM AI Pre-Warning