Power-to-gas plants convert electricity into synthetic gases such as hydrogen and methane. This technology has a key role to play in the transformation of our energy system: renewably produced synthetic gases replacing fossil fuels for industrial, transport and heating applications, where they make a decisive contribution to decarbonisation and defossilisation. This reduces greenhouse gas emissions and actively counteracts global climate change. Synthetic gases such as hydrogen and methane also allow the existing gas infrastructure to be utilised – a decisive advantage when it comes to implementing and integrating renewable energy.

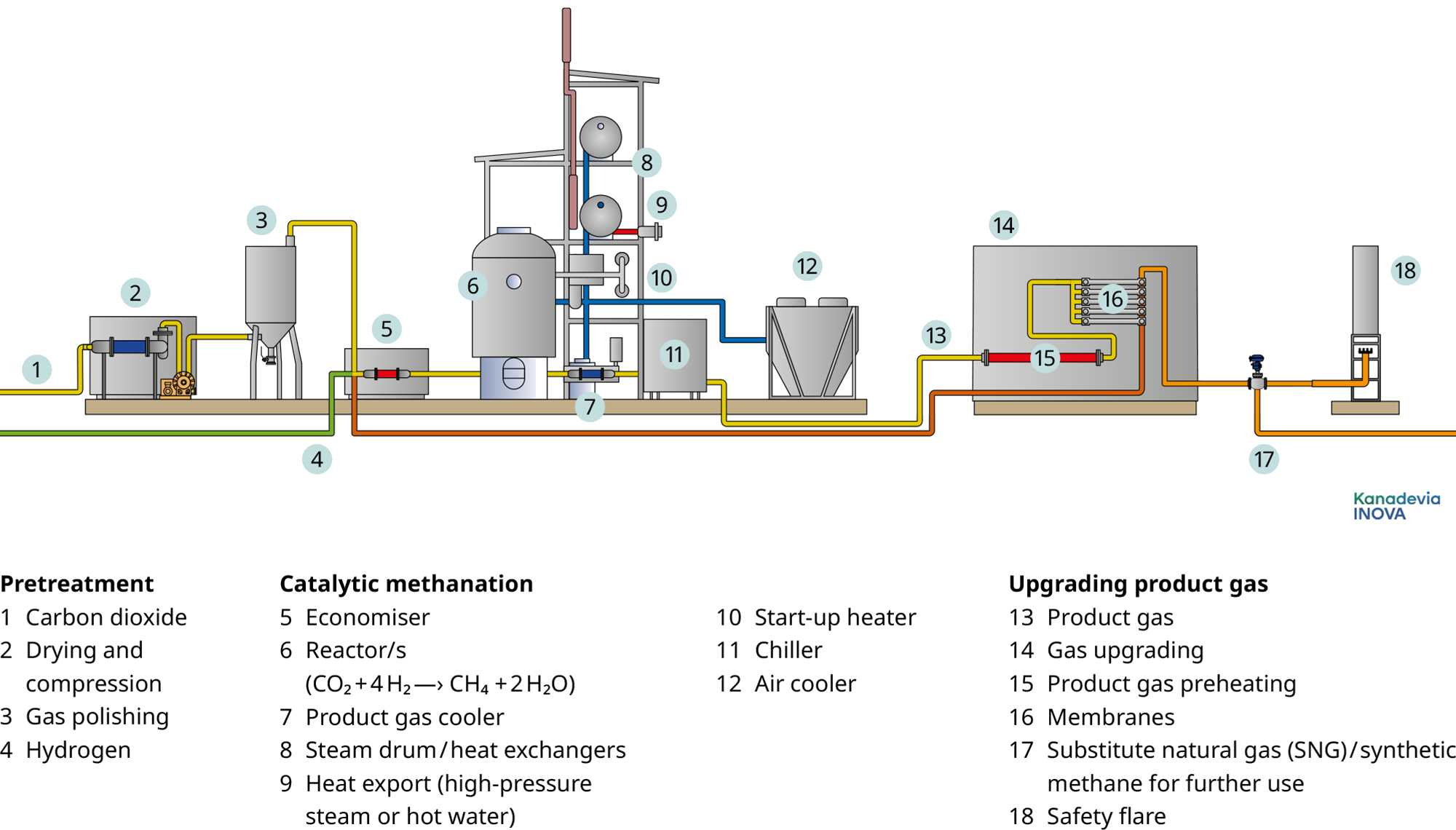

The power-to-gas process involves the use of electrolysis and methanation systems. The first step in electrolysis is to separate water (H2O) into hydrogen (H2) and oxygen (O2) with the help of electricity. The hydrogen produced can be utilised directly or for other processes. Methanation involves a reaction used to convert hydrogen and carbon dioxide (CO2) into synthetic methane (CH4) and water. The hydrogen can come directly from electrolysis plants or from synthesis gas (syngas), which is produced thermochemically from biomass or waste.

The CH4-rich product gas or substitute natural gas (SNG) resulting from methanation can be used immediately, stored in existing gas infrastructures or liquefied by additional systems.

With our complete range of services, we can support you in all phases of delivery of the system:

- Concept development

- Planning & engineering

- Execution & commissioning

- Monitoring

- Operation & maintenance

We have a wide range of services to assist you from the outset. You choose what’s right for you from our service packages:

- Feasibility studies

- Front-end engineering and design

- Basic and detail engineering

Launch an enquiry here: Schmack Biogas Online Check (schmack-biogas.com)

Technology and Services

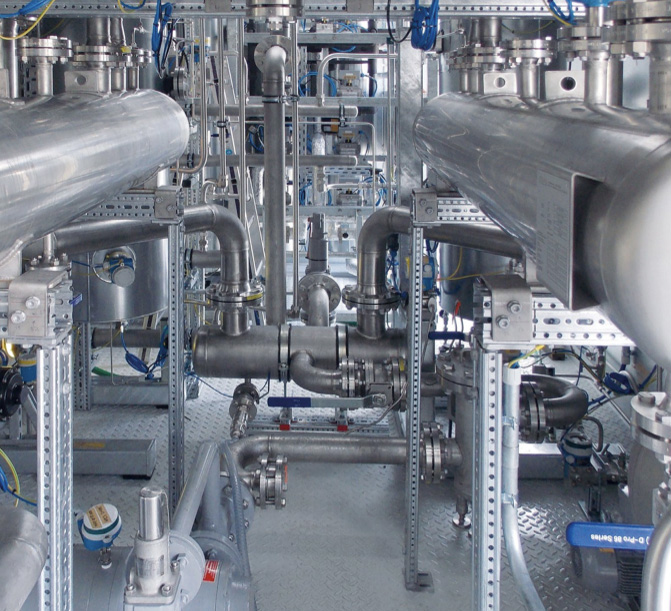

INPEX plant, Japan

Our catalytic methanation systems convert hydrogen and carbon dioxide into synthetic methane and water. A wide range of sources of CO2 gas (biogas, syngas or pure CO2) can be used.

Our catalytic methanation systems convert hydrogen and carbon dioxide into synthetic methane and water. A wide range of sources of CO2 gas (biogas, syngas or pure CO2) can be used.