Sustainability

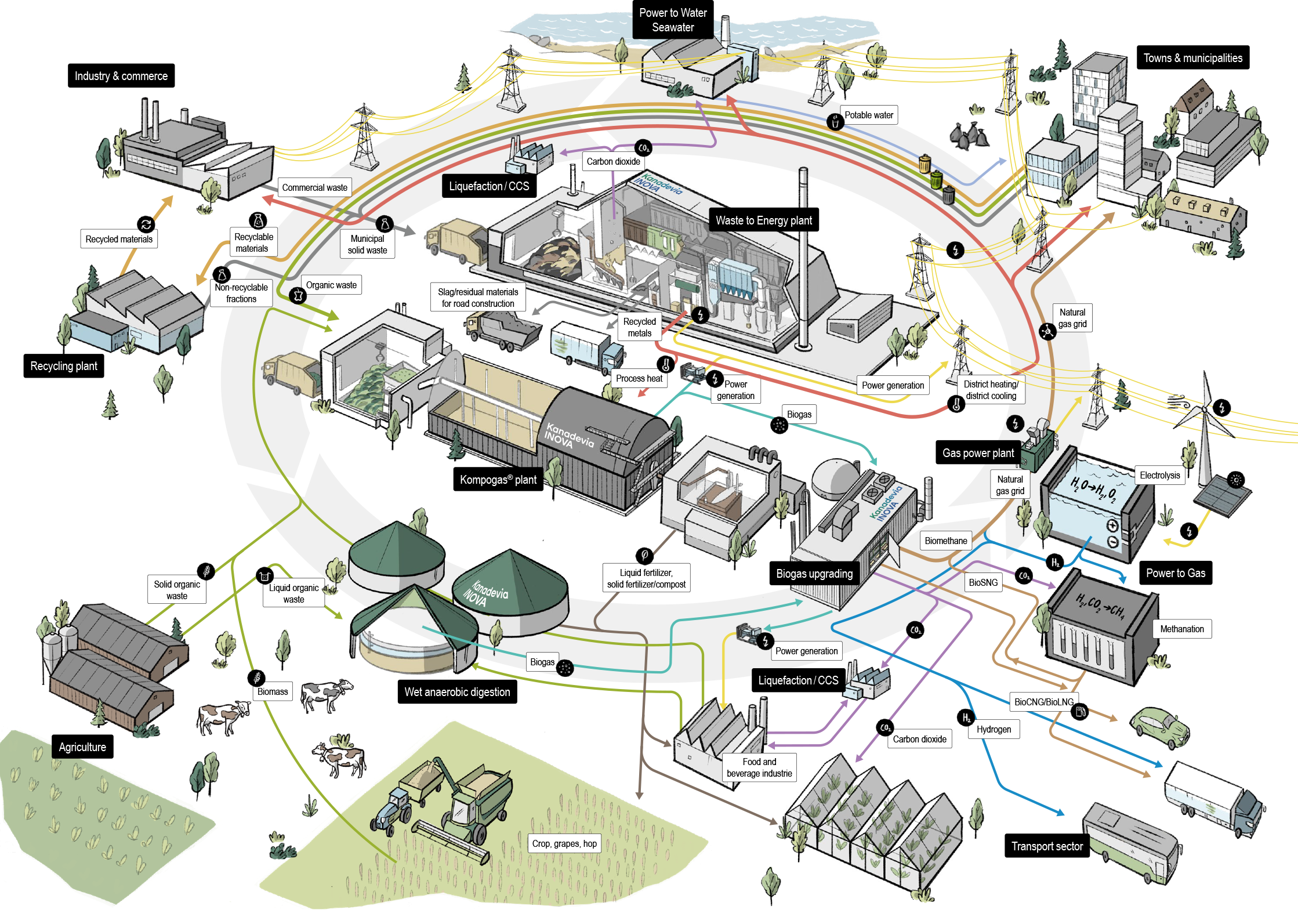

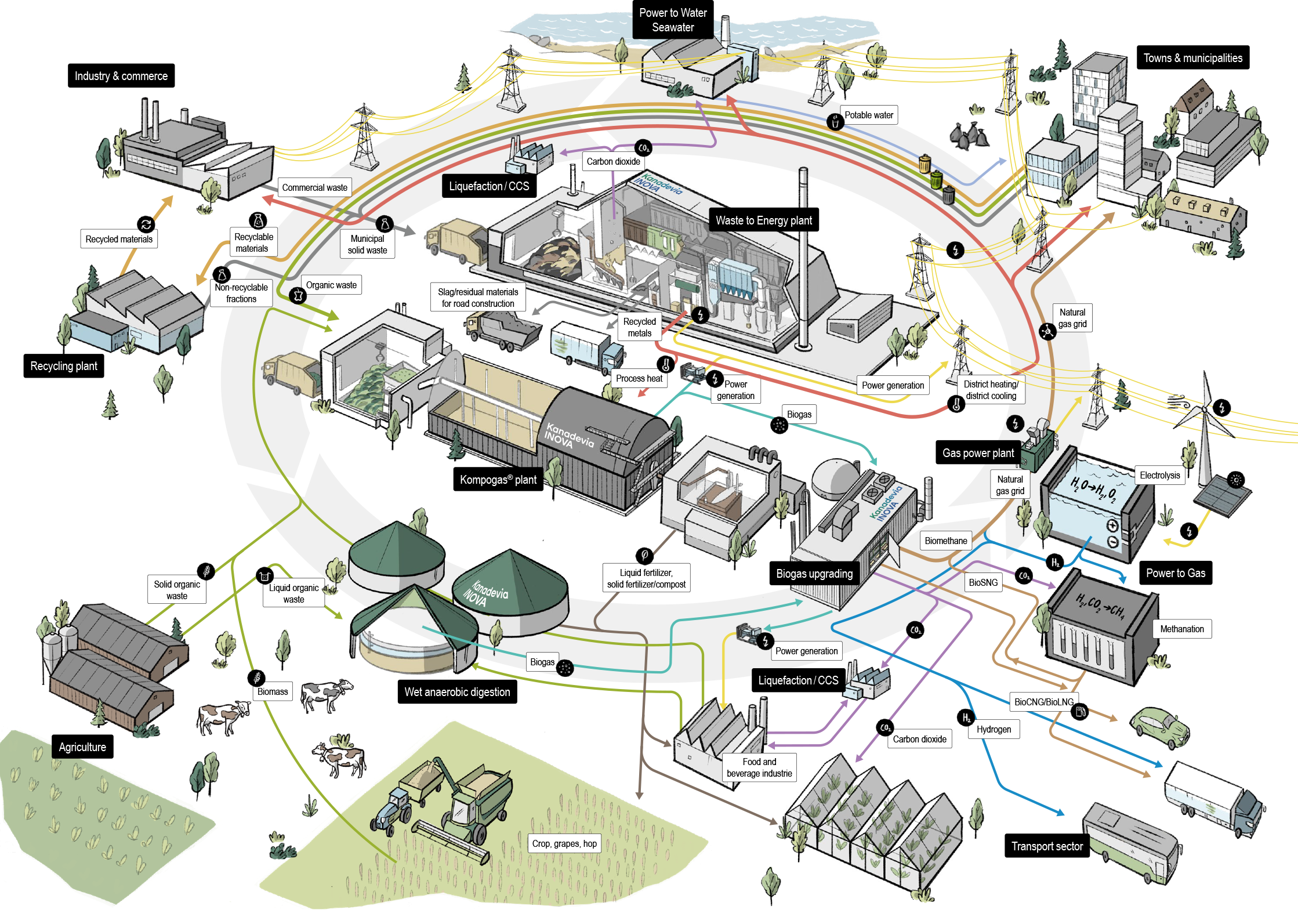

An all-encompassing look into the future of waste treatment reveals huge potential – provided that everyone involved, and their specific needs and requirements, is included in the process.

The focus is on recovering the useful materials contained in waste, disposing of non-recyclable waste hygienically and safely, and generating renewable energy on a constant basis. Thanks to state-of-the-art technologies, this concept closes gaps in the current circular economy approaches. The goal is to reduce the use of raw materials and fossil fuels to a minimum, or even to zero. In a system taking in all the relevant components, CO2 is separated out of processes wherever possible and used as a resource, or removed from the cycle by means of carbon capture and storage (CCS) approaches.

In modern waste management, municipal solid waste is collected and disposed of on a source-separated basis. This maximises the proportion of materials that can be recycled. The non-recyclable component is treated in an WtE plant along with industrial and commercial waste to recover thermal energy. Depending on requirements, the energy tied up in the waste is converted into electricity, heat, cold, process steam or hot water for municipalities and industrial and commercial enterprises. A large proportion of metals is recovered and fed back into the production cycle. The bottom ash produced in the course of waste incineration can be reused in construction. The incineration process and the operation of the plant run automatically on the basis of AI-supported combustion control systems (CCSs).

Biodegradable fractions are fermented along with biomass and organic residues from agriculture using Kompogas® to produce biogas. Residues from the anaerobic digestion process can then be used as high-grade fertiliser. The biogas can be used on site to generate electricity or can be upgraded to make biomethane.

Thanks to power-to-gas technology, the carbon dioxide produced in incineration and removed in the gas upgrading unit can be used productively in the form of SNG (synthetic natural gas). This process is powered by surplus energy from renewable sources such as photovoltaic energy or wind power. This involves two steps: First water is split into hydrogen and oxygen by introducing electricity (electrolysis). The hydrogen itself can be used directly to fuel vehicles. Or in a second step, methanation, it can be upgraded with carbon dioxide (for example from waste incineration or separated out from the biogas upgrading process) to make SNG, which can be used as a high-grade vehicle fuel. As part of an integrated approach, power-to-gas technology enables energy generated from renewable resources to be stored in the form of high-grade, climate-neutral fuels for the mobility sector.

This holistic approach to waste management – what we call the urban waste energy network – allows waste to be disposed of safely while generating a continuous source of renewable energy. The approach harnesses upgrading and recovery to maximise the recycling quota and help achieve ambitious decarbonisation goals in more or less all sectors of the economy.

For Kanadevia Inova the urban waste energy network is no far-distant utopia. It’s what we’ve geared ourselves to, setting down our commitment in our corporate strategy. We’re already broadly enough based to be able to provide WtE, digestion, biogas upgrading and power-to-gas technologies, and we’re working on refining and developing each technology on a specific basis. At the same time we’ve gained a deep understanding of the market as the operator of various installations – and are able to make a valuable contribution to creating an urban waste energy network.