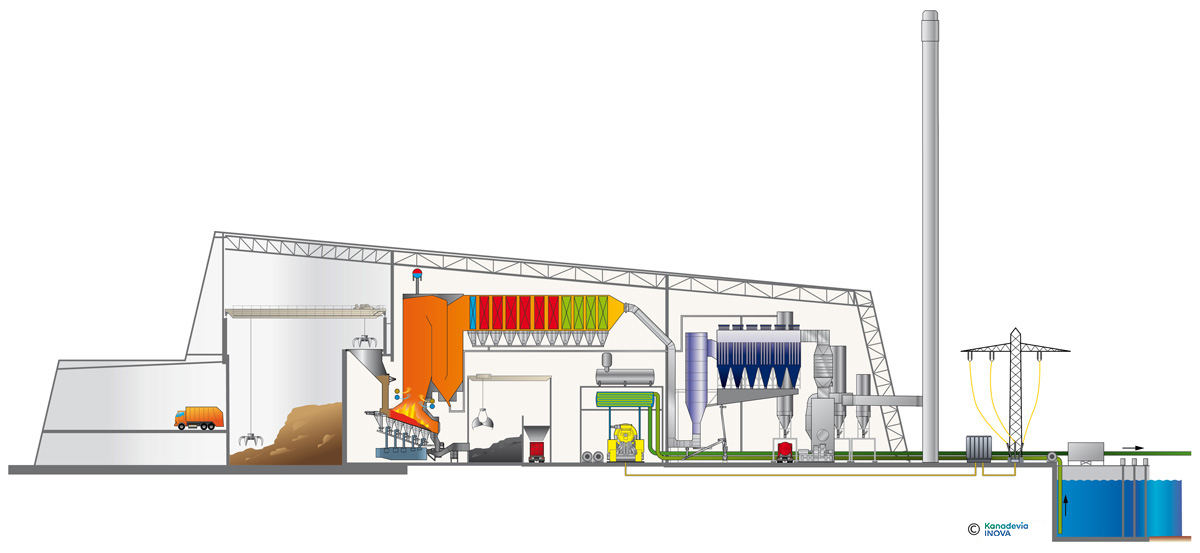

Reliable Technology – Continuously Improved and Optimised

Grate combustion is the best-proven thermal waste treatment technology for mixed municipal solid waste, and the heart of any modern, state-of-the-art Waste to Energy (WtE) plant. Kanadevia Inova has constantly optimised, developed and adjusted its proprietary grate combustion systems to meet changing statutory requirements. Grate combustion is now the most advanced technology with regard to environmental sustainability, operating reliability and cost-effectiveness.

Grate Combustion

Our in-house grate combustion technology is designed specifically for the thermal treatment of municipal solid waste. It has been constantly optimised through decades of operating experience, and now achieves an unsurpassed level of efficiency and reliability.

The core of the combustion process is a maintenance-friendly, inclined reciprocating grate, plus the following elements:

- Waste feeding system

- Air-cooled or water-cooled grate

- Combustion air system

- Flue gas recirculation system

- Advanced combustion control system

- Bottom ash extractor

Well-Proven and Reliable Combustion Technology

The rugged construction of the Kanadevia Inova grate and its insensitivity to highly heterogeneous waste fractions are why it remains the most widespread and reliable method for the thermal treatment of residual waste today. In fact, it constitutes the very heart of Waste to Energy plants, and is the technology of choice not only for untreated municipal and industrial wastes, but also for refuse-derived fuels (RDFs) and pre-treated waste.

The waste crane supplies the waste to the feed hopper and ram feeder, which doses it onto the Kanadevia Inova grate in a controlled manner. On the grate the waste is combusted in accordance with strict regulatory requirements governing residual total organic carbon (TOC) content in the resulting bottom ash.