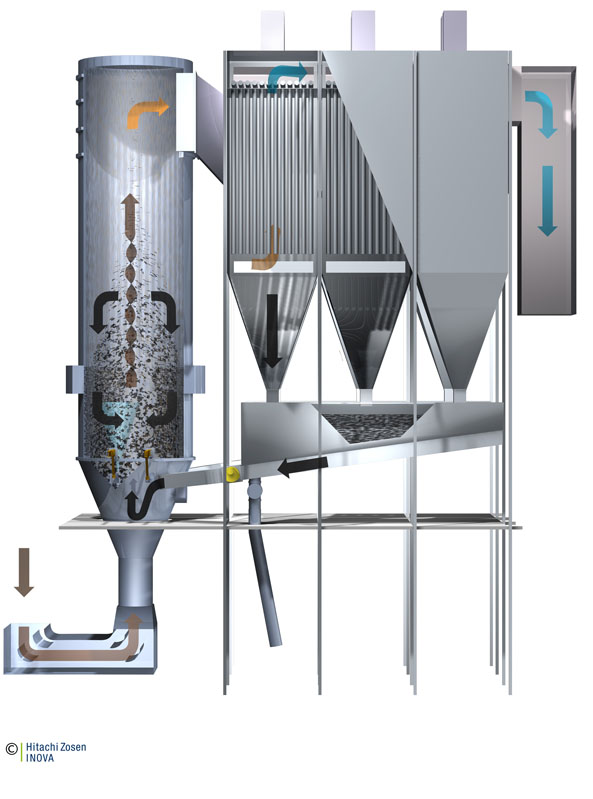

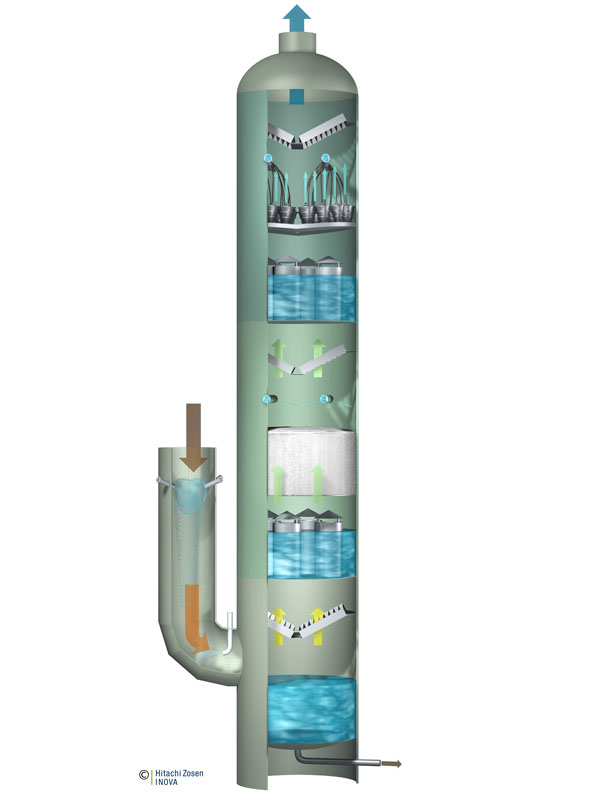

Incinerating waste produces exhaust gases laden with diverse pollutants. Different processes are used to remove these pollutants before the purified flue gas leaves the plant safely through the stack.

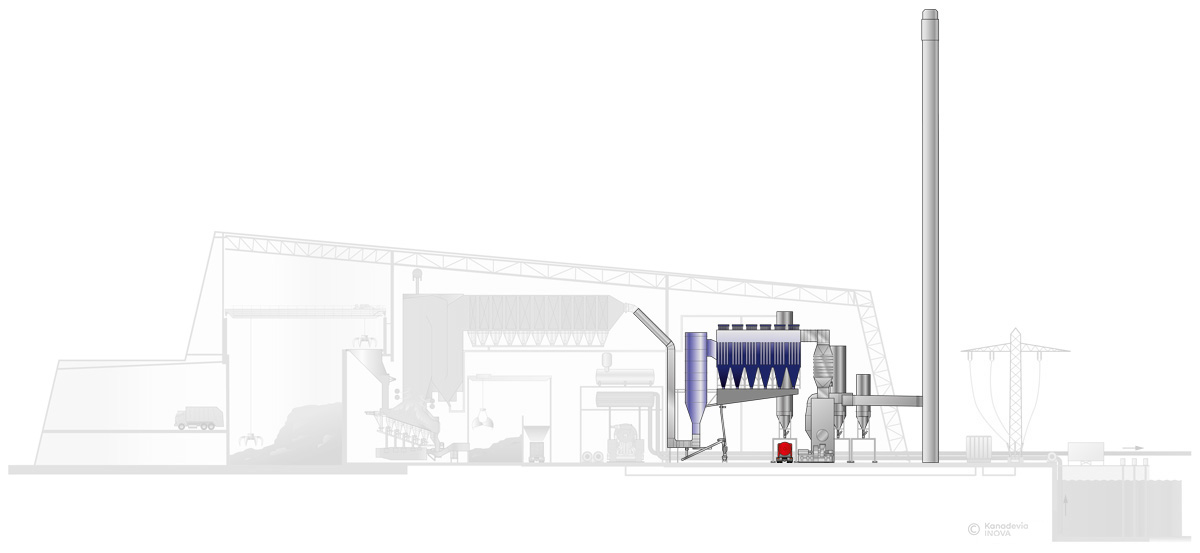

For decades Kanadevia Inova has been doing research into flue gas treatment and developing new and effective treatment systems. We harness internal synergies to optimally match and combine our combustion and flue gas treatment equipment. The numerous processes that have emerged can be used individually or together to create high-performance integrated systems.

The appropriate flue gas treatment approach is chosen in close consultation with the client. The selection criteria include regulatory air pollution limits, the client’s expectations regarding the energy efficiency of the plant, restrictions on waste water discharge, and the space available on site – to name only a few.

Typical Pollutants in the WtE Process – and What We Do to Address Them

Various pollutants are introduced into the combustion process by the waste, including oxidised combustion products such as SO2and NOxproducts, as well as substances such as hydrogen chloride and hydrogen fluoride, heavy metals, dioxins and furans. We use specific types of treatment to separate these pollutants out during the WtE process and then dispose of them appropriately. Our comprehensive range of processes enables us to cover a broad spectrum of requirements.

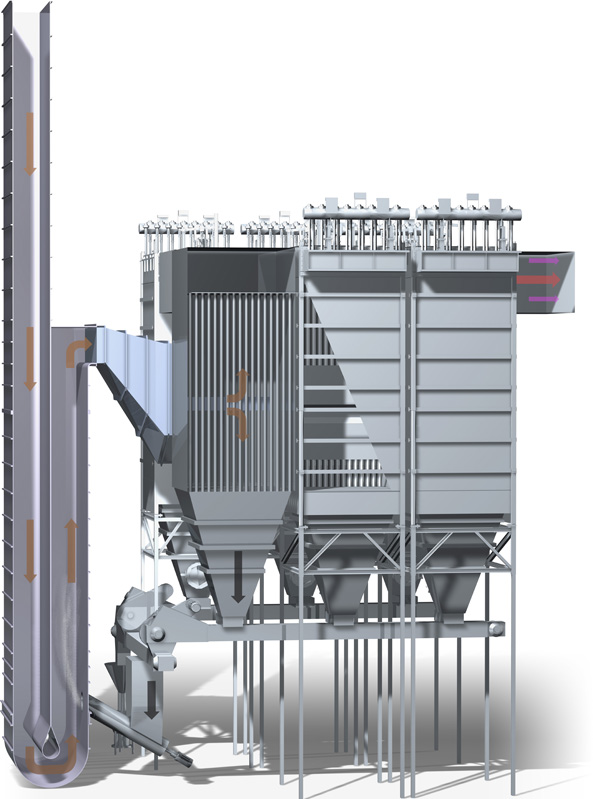

Dust

Dust

- Fabric filter

- Electrostatic precipitator

Corrosive

Acid

Gases

Corrosive Acid Gases

- Dry sorption

- Semi-dry sorption process

- Wet scrubber

Organic

Carbon

Compounds

Organic Carbon Compounds

- Adsorption onto activated carbon or lignite coke

Mercury

Mercury

- Adsorption onto activated carbon or lignite coke

Other

Metals

Other Metals

- Removed with flying dust in a fabric filter or electrostatic precipitator

Integrated Flue Gas Treatment Systems

Thanks to many years of experience, Kanadevia Inova can now offer a wide range of high-performance processes for reducing emissions. On the basis of the individual requirements and circumstances of each plant, we develop tailored integrated flue gas treatment approaches. When putting together the right overall approach we take account of the following factors:

- What is the key performance indicator for flue gas treatment? For example achieving the lowest possible emissions, optimising energy efficiency, or minimising the investment in the process, etc.?

- Type of waste, including any pretreatment

- Type of combustion process, plus waste throughput and thermal capacity

- What emission limits are to be complied with?

- Volume flow of flue gas and temperature of flue gas at the boiler

- Temperature profile along the flue gas path

- Availability and cost of water, materials/reagents and fuels/energy sources

- Availability and cost of disposing of or processing residues generated or recovered

- Energy supply options (for example feeding into a district heat network, supplying heat from a condensing scrubber, etc.)

- Restrictions on wastewater discharge

- Available space (surface, limitations due to existing design of building, etc.)

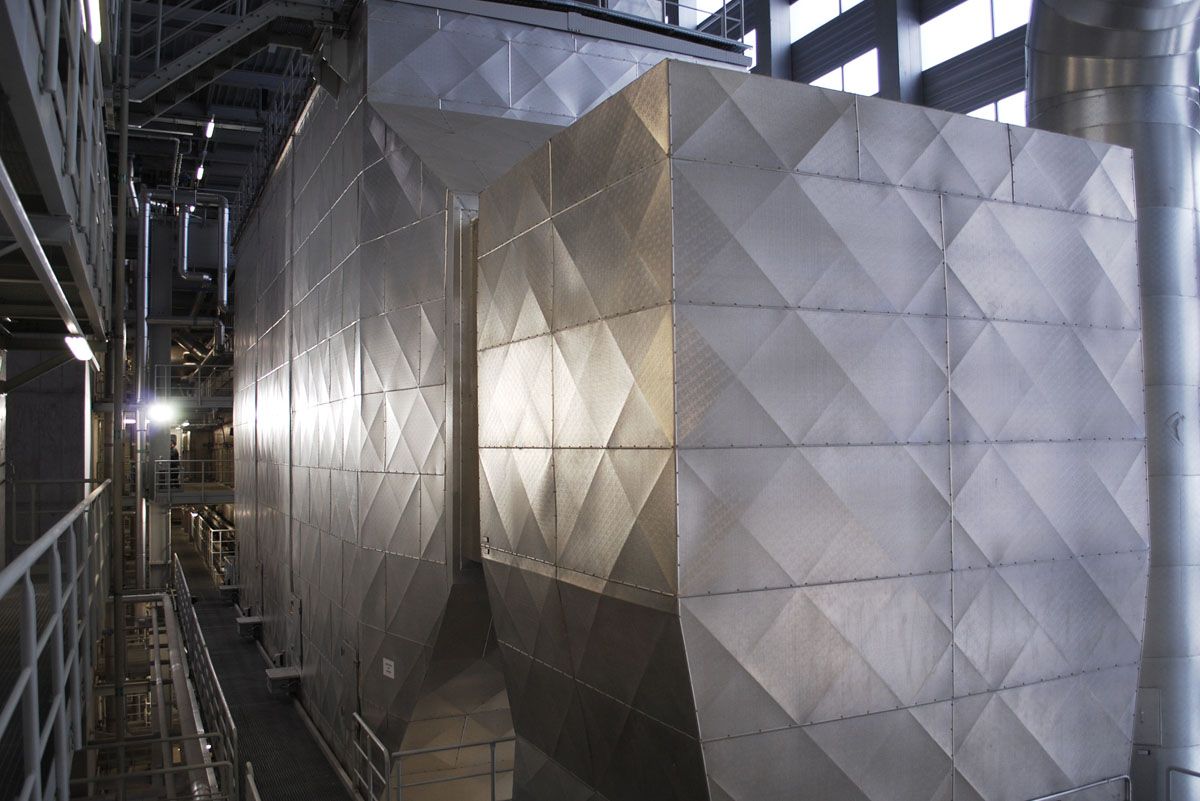

Each flue gas treatment module serves a specific purpose. Flue gas cleaning achieves the highest performance when the various components are combined – on the basis of the individual requirements of the plant. In this way, even the lowest BREF emission values can be achieved without difficulty.