Material Recovery from Ash and Slag

Thermal waste treatment produces residues which can be either reused or landfilled. The principal components are slags and ashes, consisting mostly of non-combustible waste constituents such as glass, minerals or scrap metals. Flue gas cleaning also forms reaction products. The volume and nature of the residues produced depend mainly on the composition of the waste and the process used in the particular treatment concept. With an intelligent secondary treatment process, large parts of these materials can often be reused.

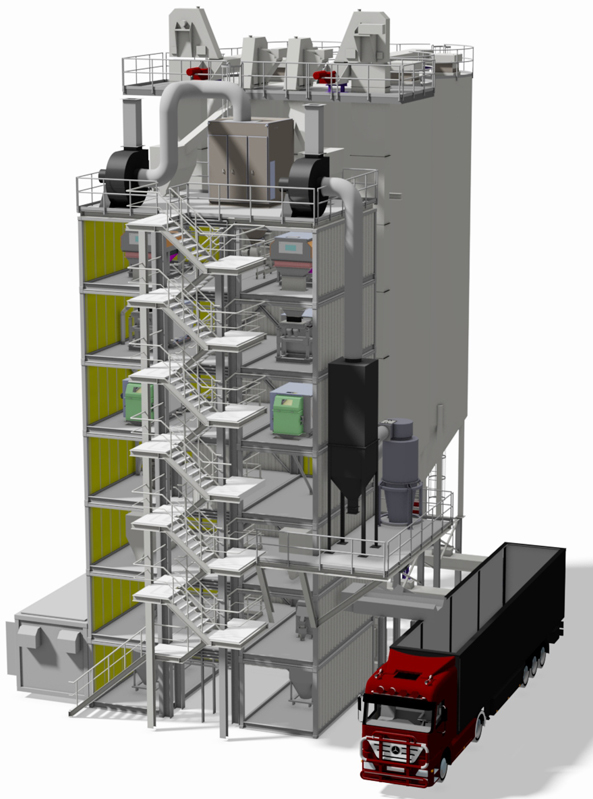

InovaRe

InovaRe by Kanadevia Inova: Efficient Material Recovery from Waste

Recovering metals from bottom ash is an aspect of urban mining that is becoming increasingly significant for the operators of WtE plants. As well as enabling valuable materials such as copper and aluminium to be recycled profitably from the bottom ash, it also saves huge amounts of CO2. Recycling aluminium from bottom ash requires just 10% of the amount of the energy consumed in primary production.

In addition to the tried-and-tested wet discharge process, Kanadevia Inova also offers InovaRe, a complete modular solution for the efficient recovery of materials from bottom ash. Developed in-house, it is suitable for both wet and dry discharge.

Fly Ash Washing

Stabilisation and Product Recovery

If fly ash is collected separately from bottom ash and flue gas cleaning residues, two different methods may be applied to remove or immobilise fly ash contaminants:

- Acid washing of fly ash using acidic scrubber blowdown removes heavy metals in a recyclable form and produces a fly ash which can be disposed with the bottom ash

- Neutral washing followed by solidification by adding binders to condition the fly ash into a leach resistant matrix